Environmental

Environmental Sustainability Goals

Achieve Net Zero Carbon Emissions by 2050

Ongoing

All manufacturing factories to be ISO 14001 Environmental Management System certified by 2030

We are certified with ISO 14001:2015

Targets to achieve a reduction of 10.0% in global water withdrawal in 2030 with FYE2022 as a baseline

Ongoing

| Reduction of water withdrawal for Year |

m³ (in %) |

| 2022 | Baseline year |

| 2023 | 0.2 |

| 2024 | 0.2 |

Targets to achieve a reduction of 15.0% for our absolute GHG emissions for Scope 1 and Scope 2 in 2025 with FYE2022 as a baseline

Ongoing

| Reduction of co2e for Year |

GHG Emission (Scope 1 & 2) (in %) |

| 2022 | Baseline year |

| 2023 | 8.0 |

| 2024 | 9.3 |

Targets to achieve a reduction of 50.0% for our absolute GHG emissions for Scope 2 in 2030 with FYE2022 as a baseline

Ongoing

| Reduction of Co2e for Year |

GHG Emission (Scope 2) (in %) |

| 2022 | Baseline year |

| 2023 | 7.5 |

| 2024 | 8.8 |

Water

Water is a very important yet limited resource in our manufacturing plants where this precious commodity is critical to our glove production processes. At Hexcare, we are committed to managing and using water in the most cost-efficient way that also promotes the long term sustainability of the environment as well. Our Group targets to achieve a reduction of 10.0% in overall water withdrawal in 2030 with FYE2022 as a baseline. Consequently, some of the water saving initiatives that the Group has put in place include:

i. A rain water harvesting system at our Malaysia glove production plants, which saved approximately 1000 cubic meter of water withdrawal per year; and

ii. Installed filters in the leaching tanks to manage the sludge accumulation, reducing the frequency of water changes and downtime to clean the tanks at Rubberex (M) Sdn Berhad. Through the implementation of this initiative, we reduced the water change frequency from twice a week to once a week, thereby saving approximately 740 cubic meters of water withdrawal in FYE2024.

Hexcare’s glove production plants are housed in within a single location in Ipoh, Perak, Malaysia where we deploy well-established waste water treatment plants and water recycling systems on-site to manage the consumption of water and address water security risks.

Recycled water is reused for toilet flushing, general cleaning, gardening, and other non-critical functions within factory grounds. In addition to the systematic monitoring of daily water consumption, the quality of effluent discharges is also closely tracked to ensure that processed water is safely treated before it released to our drainage and local river systems.

Hexcare’s water withdrawal is primarily sourced from the local municipal water supply. In order to minimize dependency on municipal water sources, we are in the process of upgrading our on-site rainwater harvesting system at our Rubberex Alliance Sdn Bhd sites, that would be capable of capturing approximately 3,000 cubic meters of rain water a year, for recycling and use within our factory operations. With this, two out of the three sites, which constitute 66.7% throughout the company, will be equipped with rainwater harvesting systems. The reduction of municipal water consumption is expected to create more self-sustaining plants, improve efficiency and result in cost savings for the Group.

Besides pollution and emission controls, the Group’s effluent discharges are effectively treated before release to the river systems and reused in the factories. The Group is guided by the Environmental Quality (Industrial Effluent) Regulations 2009 and is in compliance to the design and construction of its industrial effluent treatment systems as well as specifications of industrial effluent treated and/or disposed. The quality of effluent discharges is closely monitored to ensure that processed water is safely treated and pose no threat to the environment before it is released to our drainage and local river systems. In FYE2024, there were no incidences of non-compliances relating to water quality or quantity permits, standards or regulations that resulted in fines, penalties or warnings from the authorities.

In FYE2024, our Malaysian plants treated and released approximately 835,000 cubic meters of water back to the local river systems. Compared to water withdrawn from our national water source of 659,000 cubic meters, the ratio of 1.27 implied a higher volume of treated water released relative to that consumed and has improved from the year before. The Group has set a target to achieve a reduction of 10.0% in global water withdrawal in 2030 with FYE2022 as a baseline. As of FYE2024, we have achieved a 0.4% reduction toward our 10.0% target in global water withdrawal.

| FYE2024 mil m³ |

FYE2023 mil m³ |

FYE2022 mil m³ |

|

| Volume of Water Treated *(Back to local river system) |

0.84 | 0.94 | 0.80 |

| Volume of Water Withdrawn **(Withdrawn from local municipal water source) |

0.66 | 0.82 | 0.62 |

| Ratio (Water Treated : Water Withdrawn) | 1.27 | 1.15 | 1.29 |

| Volume of water withdrawn in water-stressed region | Nil | Nil | Nil |

*Water treated is equivalent to water discharged

**Water withdrawn is equivalent to water consumed

The Group also primarily operates in Malaysia, within Ipoh, Perak and Subang, Selangor, where, according to the WRI (World Resources Institute), are not considered water stressed areas (https://www.wri.org/applications/aqueduct.water-risk-atlas). The Group targets to maintain these bases and have no immediate plans to relocate to any water-stressed regions in Malaysia or overseas within the next five(5) years. Nevertheless, we acknowledge that floods, droughts and other water related risk issues brought on by unpredictable weather patterns and climate change will likely impact on the way businesses are organized and operated in future.

Energy

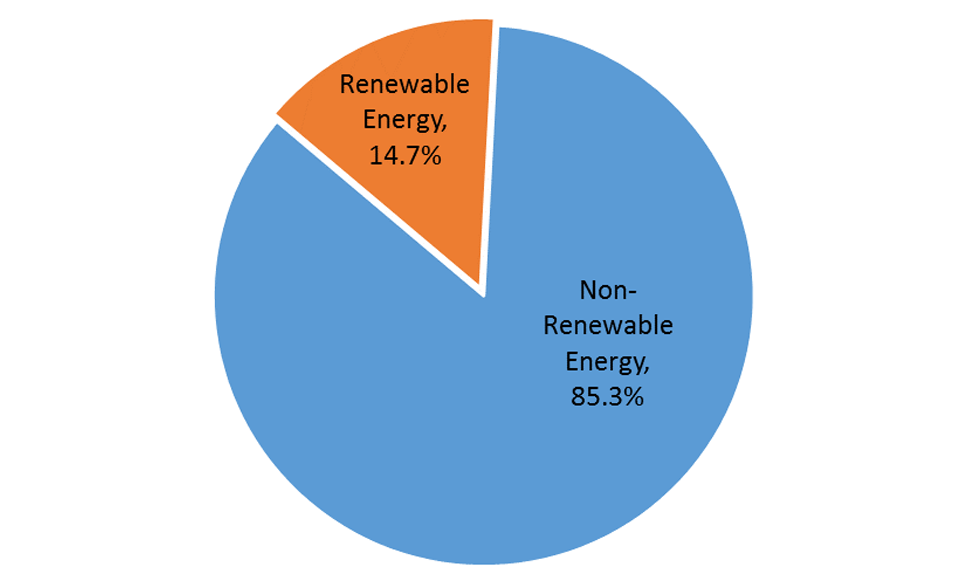

In FYE2024, the Group also accomplished notable milestones in our ongoing commitment to environmental sustainability. The savings in electricity consumption was primarily driven by our intentional shift to solar energy which was a move towards a more sustainable and clean energy source, in line with our objective to minimize carbon emissions. Following lower production intensities, the reduction in electricity, diesel and petrol consumption were also attributable to the decrease in production demand, which correspondingly led to diminished energy needs.

| Energy Consumption |

FYE2024 |

FYE2023 |

FYE2022 |

| Petrol | 137 | 55 | 55 |

| Diesel | 213 | 226 | 484 |

| Natural Gas | 39,852 | 82,021 | 43,548 |

| Electricity (from TNB) | 12,575 | 19,430 | 20,996 |

| Electricity (from solar panels) | 1,843 | 1,565 | 78 |

| Woodchips and PKS | 15,042 | 15,927 | 32,227 |

| Total | 69,662 | 119,224 | 97,388 |

Solar panels installed at Hexcare’s glove production plants in Ipoh, Malaysia

Note:

- Non-renewable energy: Diesel, electricity from TNB and natural gas usage from mobile and stationary equipment

- Renewable energy: Energy consumption from renewable sources generated from solar panels, woodchips and PKS

Above all else, in our quest for continuous improvements and innovations in efficient energy consumption, Hexcare has in place an internal Energy Savings Committee, comprising 14 staff and competent personnel from various departments, who meet at least once quarterly to review and promote responsible energy use within the Group, strengthening our long-term commitment towards Net Zero Carbon Emission 2050.

The electricity yield from our solar panels in FYE2024 was 2,476 MWh, of which 1,843 MWh was utilized at our plants and 633 MWh subsequently exported back to the national electricity grid, Tenaga National Berhad (“TNB”). Based on this preliminary data, the cost savings generated for year 2024 amounted to approximately RM528,000. Since commencement in FYE2024, we have effectively reduced a total of 3,324 metric ton (MT) of carbon dioxide (CO2) emission with the installation of the solar system.

| Solar Panels |

FYE2024 |

FYE2023 |

FYE2022 |

| Electricity yield (MWh) | 2,476 | 1,958 | 212 |

| Electricity utilized (MWh) | 1,843 | 1,565 | 78 |

| Electricity exported back to TNB (MWh) | 633 | 393 | 135 |

| Reduction in MT Co2e | 1,931 | 1,527 | 166 |

3Rs -Recycle, Reduce and Reuse

i) Preservation of Forests and Biodegradability

The 3Rs mantra for the Environment is all the more relevant today as we confront the challenges of climate change, greenhouse gas emissions and depletion of natural resource. Simply put, correct applications of the 3Rs help to reduce the burden on our environment and saves our precious planet.

The world’s forests play a vital role in regulating our climate, absorbing carbon dioxide from the atmosphere and effectively counteract global warming. In our quest to tackle the challenges of climate change and protect the destruction of forests and the precious biodiversity in them, the Group consciously sources its wood and paper products such as packaging materials, wooden pallets and stationeries from Forest Stewardship Council (FSC) certified sources and materials. Products that carry the FSC label are made from 100% recycled materials or are sourced from FSC-certified forests, essentially helping to reverse the effects of deforestation and preserving our environment.

Hexcare’s household and certain industrial gloves produced in Malaysia are largely made from natural rubber – they are recyclable as well as biodegradable in soil where the gloves naturally disintegrate into organic matter over time, causing no harm to the environment or water systems. Where possible, plastic and other synthetic non-biodegradable matters in our shipped goods are also replaced with wood products that are sustainable and renewable.

According to Malaysian Meteorological Department (MET Malaysia) or World Meteorological Organization (WMO), Malaysia is generally free from extreme climate events like typhoons, fires, and droughts, and, therefore, may not experience significant impacts on product manufacturing and raw material availability. Additionally, in response to our government’s enforcement of the gradual phase-out of single-use plastics, Hexcare is proactively seeking to transition to plastic made from 30% Post-Consumer Recycled (PCR) or Post-Industrial Recycled (PIR) material and 70% virgin plastic resin in the near future.

In another tangible effort to reduce carbon footprint, where possible, the Group also promoted the packaging of gloves in the doubled-up 200 piece-pack or 2,000 pieces per carton style so as to optimize paper and chemicals usage, contributing to less wastes, lower costs and a kinder environment in the long run.

To promote the culture of Recycle, Reduce and Reuse, staff and workers are also encouraged to deposit recyclable items such as used paper, glass and plastic wares at designated well-marked storage bins located strategically within the factory grounds. Larger, disposed industrial containers and bags containing contaminated wastes and chemicals, such as of the type SW409 are also collected for recycling by a specific licensed contractor for off-site scheduled waste recovery on a regular basis.

ii) Scheduled Waste

Scheduled waste is any waste that has hazardous characteristics and the potential to impact the environment and/or harm the public if exposed. At Hexcare, responsible waste and pollution management entail the proper and correct disposal of wastes or unwanted by-products in accordance with the Department of Environment (“DOE”) Scheduled Wastes Regulations 2005 (Environmental Quality Act 1974).

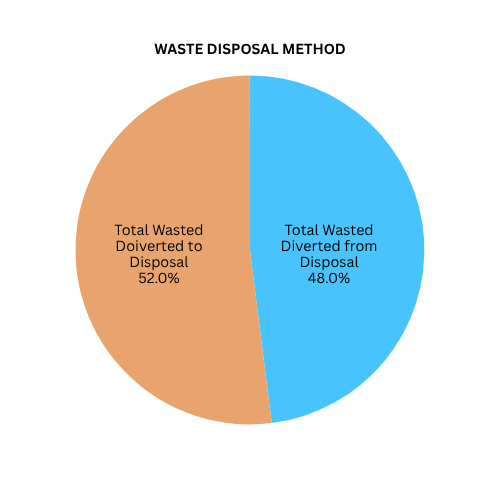

The types of scheduled wastes generated by our plants include latex sludge, clinical waste, waste acetone, contaminated containers and other solid wastes. In FYE2024, 693.5 MT of scheduled waste was generated as by-products of the Group’s glove operations, of which latex sludge and compounded latex lumps make up the highest proportion of scheduled waste generated.

| Code | Scheduled or Hazardous Waste Generated | Total Weight (MT) | Disposal Method |

| SW 102 | Battery waste | 0.5 |

To reuse, if possible. To dispose to approved disposal facility, if not reusable. |

| SW 109 | Fluorescent Bulbs | 0.2 | |

| SW 110 | Electronic Waste | 0.2 | |

| SW 305 | Oil waste (Spent Lubricant Oil) | 46.6 | |

| SW 307 | Oil Waste | 6.0 | |

| SW 321 | Compounded Latex Lump waste | 229.5 | |

| SW 408 | Contaminated Soil | 4.8 | |

| SW 409 | Contaminated Containers | 37.3 | |

| SW 321 | Sludge | 366.7 | Approved disposal facility/ Waste management company either landfill or combustion. |

| SW 404 | Clinical Waste (RTK) | 0.0 | |

| SW 410 | Contaminated Rags | 1.5 | |

| Total | 693.5 | ||

The disposal and management of such wastes were carried out by competent skilled personnel under the watchful eye of Management to ensure that there is no contamination of ground water, surface water and air quality that could harm the environment or affect human health. In FYE2024, the following such wastes were recorded, managed and disposed appropriately by the Group:

| Waste |

FYE2023 |

FYE2023 |

FYE2022 |

| Hazardous Waste | 693.5 | 698.1 | 901.6 |

| Non-Hazardous Waste | 15.2 | 11.7 | N/A |

| Total Waste Diverted from Disposal | 340.5 | 198.1 | 365.6 |

| Total Waste Diverted to Disposal | 368.2 | 511.7 | 536.0 |

*Non-hazardous waste consisting of mixed plastic, carton packaging, and damaged pallets

Scheduled waste disposal being carried out at Hexcare’s glove production plant in Ipoh, Malaysia

Climate change

The need for climate change risk management is more urgent than ever considering the scale of adverse economic impacts of human activities on the environment today. At Hexcare, we address this risk by computing and monitoring greenhouse gas emissions from the plants’ production processes and operations of our offices in Malaysia.

As a responsible global corporate citizen, we believe that it is important to continuously reduce the impact of GHG emissions from year to year through improving operational efficiencies and applying green technologies where feasible. We established our emissions data table to represent Hexcare’s operational carbon emissions following the guidelines in the Greenhouse Gas (GHG) Protocol, which is a standard governing the accounting and reporting of seven GHG covered by the Kyoto Protocol, and subsequently taken pro-active steps to reduce them. In the process, we have also defined the operational boundaries for the purpose of such calculation, taking into account the scopes of both direct and indirect emissions within the boundaries. The emission factors used were made with reference to recognized sources such as the Malaysian Green Technology Corporation’s website (CDM Electricity Baseline for Malaysia), the Department for Environment (DOE), Food and Rural Affairs (Defra) UK GHG Conversion Factors and the Intergovernmental Panel on Climate Change (IPCC), which are relevant to our operations.

Hexcare is committed to an absolute GHG emissions decreases for Scope 1 and Scope 2 by 15.0% by 2025, and has set a long-term target of absolute GHG emissions reduction for Scope 2 by 50.0% by 2030, using FYE2022 as the baseline.

| GHG Emission | CO2e for Year (MT) | |||

| FYE2024 | FYE2023 | FYE2022 | ||

| Scope 1 | Petrol & Diesel | 92 | 78 | 153 |

| Natural Gas | 9,051 | 17,660 | 9,309 | |

| Woodchips and PKS | 8,080 | 8,559 | 17,330 | |

| Sub Total | 17,223 | 26,297 | 26,792 | |

| Scope 2 | Purchase Electricity | 7,356 | 11,366 | 12,283 |

| Sub Total | 24,579 | 26,297 | 26,792 | |

| Total (Scope 1 & 2) | 24,579 | 37,663 | 39,075 | |

| Scope 3 | Purchase goods and services | 98 | 122 | 93 |

| Upstream Transportation and Distribution | 469 | 642 | N/A | |

| Waste generated in operations | 398 | 493 | 469 | |

| Business Travel | 16 | 39 | 24 | |

| Employee Commuting | 332 | 309 | 278 | |

| Downstream Transportation and Distribution | 1,436 | 1,728 | N/A | |

| Investment | N/A | N/A | 930 | |

| Sub Total | 2,749 | 3,333 | 1,794 | |

| Grand Total (Scope 1,2 & 3) | 27,328 | 40,965 | 40,869 | |

The Group’s natural gas emissions under Scope 1 and electricity emissions under Scope 2 saw approximate reductions of 48.7% and 35.3% in CO2e discharges, respectively, when comparing FYE2024 to FYE2023. These decreases are primarily attributed to the reduction in energy consumption at our production lines owing to lower outputs and operational hours in the current year. Our Scope 3 emissions data also recorded a decrease in indirect CO2e from the value chain of the Group’s upstream and downstream operations in FYE2024 compared to FYE2023.

Notes:

Scope 1 emissions refer to direct CO2e emitted from sources that are owned by the Group, such as our machineries and company owned vehicles

Scope 2 emissions refer to indirect CO2e emitted from the consumption of purchased electricity

Scope 3 emissions refer to indirect CO2e emitted from the value chain of our company, including both upstream and downstream emissions

Hexcare is dedicated to transitioning to a low-carbon economy and continually implements measures to address climate change through adaptation. Our adaptation initiatives include adapting low emissions technologies such as Electric Vehicle (“EV”) car and forklifts, as well as utilizing a solar photovoltaic power generation system for our operations. This strategic initiative not only demonstrates our commitment to reducing the impact of climate change and improving efficiency but also plays a pivotal role in our overarching efforts to decrease Scope 1 and Scope 2 GHG emissions.

Hexcare is very much conscious of rapidly rising climate change risks, including those that are Physical and Transitional. In response, we proactively identify and manage such risks and opportunities that materially impact our value creation abilities. Driven by our in-house ESG Committee and under the direction of the Board of Directors of Hexcare who oversees the overall management of sustainability matters in the Group, including climate change, Mr Khoo Chin Leng and Mr Goh Hsu-Ming are tasked with driving the development of the group wide Net Zero Target and are committed to ensuring the integration of climate–related initiatives throughout the Group. This include initiatives focused on reducing energy consumption and emissions, managing water and waste, as well as addressing potential climate-related impact on facilities and operations. In the process, we also acknowledge the following risks and opportunities that are currently present in our Sustainability journey:

Risks

• Climate change related disclosures and regulations that would impact on our financial and regulatory reporting; and

• Reallocation of financing from financial institutions into other green-intensive investments that would affect our business funding.

Opportunities

• Management of climate change risks and adoption of greener technology could result in less wastages and contribute to overall cost savings for the Group;

• Stakeholders’ trust and perception could be improved through effective emissions management and disclosures; and

• Positive differentiation in the market for long-term value creation that would benefit stakeholders.