Sustainability

Environmental, Social and Governance (ESG)

The Board of Directors and Management of Hexcare are committed to applying Environmental, Social and Governance (ESG) considerations in our business decisions as we strive towards creating long term business success and value for our stakeholders. Guided by the internationally recognised United Nations Sustainability Development Goals and aspirations, we seek to adopt strategic approaches to support and empower communities, encourage social inclusivity and improve the long-term health of the natural environment we live in. At Hexcare, we also address climate change and reinforce our efforts towards decarbonization, in line with Malaysia’s goal towards Net Zero Carbon Emission by year 2050.

The balancing of ESG values with the interests of stakeholders is essential in improving investor perception and public trust that works towards value enhancement for stakeholders in the long run. We recognise that climate change, directly and indirectly, affects our profitability and sustainable growth, hence it is crucial to protect these by mitigating and adapting to climate related risks.

Hexcare also believes that as a responsible corporate citizen, one would have an obligation in making the earth a better place to live in through responsible investing, besides weighing on an appropriate risk-return profile for its investments. Accordingly, Hexcare incorporates these principles of sustainability in line with our core values of Integrity, Loyalty and Hard Work.

FTSE4Good Bursa Malaysia Index and FTSE4Good Bursa Malaysia Shariah Index

Our efforts to be a responsible and sustainable organization have enabled us to be included as a constituent in the FTSE4Good Bursa Malaysia (“F4GBM”) Index and FTSE4Good Bursa Malaysia Shariah (“F4GBMS”) Index since December 2022. FTSE Russell (the trading name of FTSE International Limited and Frank Russell Company) confirms that Hextar Healthcare Berhad has been independently assessed according to the FTSE4Good criteria, and has satisfied the requirements to become a constituent of the FTSE4Good Index Series. Created by the global index provider FTSE Russell, the FTSE4Good Index Series is designed to measure the performance of companies demonstrating strong Environmental, Social and Governance (ESG) practices. The FTSE4Good indices are used by a wide variety of market participants to create and assess responsible investment funds and other products.

UNITED NATIONS GLOBAL COMPACT

Hexcare is committed to upholding the principles of the United Nations Global Compact (UNGC) in our business operations. We are dedicated to fostering ethical business practices, promoting human rights, protecting the environment, and working towards the achievement of sustainable development goals that are closely related to ESG. By aligning with the UNGC, we strive to contribute to a global community that values responsible and sustainable business conduct, fostering a better and more equitable world for current and future generations.

What Our Managing Director Say

“At Hexcare, we are committed to integrating sustainability through responsible business plans across our Group’s operations. We seek to foster a sustainable culture that promotes long term economic prosperity, protects the environmental and safeguards high social values.”

“In terms of climate change, we are also committed to achieving a carbon neutral position of our own emissions by 2030 and a Net Zero Carbon Emissions target by 2050, in line with the UN’s Sustainable Development Goals (SDGs) on Climate Action. We have already integrated renewable energy in our plant and will continue to invest in other low-carbon efficient technologies as we embark on this sustainability journey. Notwithstanding, we will also work collaboratively with our customers and evaluate our supply chains to deliver on our commitment towards a more sustainable future.”

Khoo Chin Leng

Group Managing Director

ESG AT A GLANCE

Hextar Healthcare Berhad is committed to

The United Nations Sustainable Development Goals (UN-SDG) towards a decarbonization pathway while ensuring long-term value creation for the organization

Environmental

Environmental Sustainability Goals

Achieve Net Zero Carbon Emissions by 2050

Ongoing

All manufacturing factories to be ISO 14001 Environmental Management System certified by 2030

We are certified with ISO 14001:2015

Water

Water is a very important yet limited resource in our manufacturing plants where this precious commodity is critical to our glove production processes. At Hexcare, we are committed to managing and using water in the most cost-efficient way that also promotes the long term sustainability of the environment as well. Our Group targets to achieve a reduction of 10% in overall water withdrawal in 2030 with FYE22 as a baseline. Some of the water saving initiatives that the Group has put in place include:

Implemented

(i) a rain water harvesting system at our Malaysia glove production plants, which saved approximately 1000 meter cubes of water withdrawal for toilet flushing purposes since November 2022.

(ii) Installed filters in the leaching tanks to manage the sludge accumulation, reducing the frequency of water changes and downtime to clean the tanks at Rubberex (M) Sdn Berhad. Through the implementation of this initiative, we reduced the water change frequency from twice a week to once a week, and we have successfully saved approximately 740 meter cubes of water withdrawal per year throughout the Group.

Rubberex (M) Sdn Bhd

Rubberex Alliance Sdn Bhd

On-going

(i) Continuous improvements in production process parameters, particularly in the leaching process that targets reduction in water usage by 20% by end 2023; and

(ii) Re-routing pipes and reusing water from certain operational processes into the production processes where viable and feasible.

Hexcare's glove production plants are housed in within a single location in Ipoh, Perak, Malaysia where we deploy well-established waste water treatment plants and water recycling systems on-site to manage the consumption of water and address water security risks.

Recycled water is reused for general cleaning, gardening, and other non-critical functions within factory grounds. In addition to the systematic monitoring of daily water consumption, the quality of effluent discharges is also closely tracked to ensure that processed water is safely treated before it released to our drainage and local river systems.

Hexcare’s water withdrawal is primarily sourced from the local municipal water supply. In order to minimize dependency on municipal water sources, we are in the process of upgrading our on-site rainwater harvesting system at the Rubberex Alliance Sdn Bhd sites, that would be capable of capturing approximately 3,000 meter cubes of rain water a year, for recycling and use within our factory operations. With this, two out of the four sites, which constitute 50% throughout the company, will be equipped with rainwater harvesting systems. The reduction of municipal water consumption is expected to create more self-sustaining plants, improve efficiency and result in cost savings for the Group. This system is expected to be fully operational by end of 2023.

Besides pollution and emission controls, the Group’s effluent discharges are effectively treated before release to the river systems and reused in the factories. The Group is guided by the Environmental Quality (Industrial Effluent) Regulations 2009 and is in compliance to the design and construction of its industrial effluent treatment systems as well as specifications of industrial effluent treated and/or disposed. The quality of effluent discharges is closely monitored to ensure that processed water is safely treated and pose no threat to the environment before it is released to our drainage and local river systems. In FYE2022, there were no incidences of non-compliances relating to water quality or quantity permits, standards or regulations that resulted in fines, penalties or warnings from the authorities.

In year 2022, our Malaysian plants treated and released approximately 802,000 meter cubes of water back to the local river systems. Compared to water withdrawn from our national water source of 622,000 meter cubes, the ratio of 1.29 implied a higher volume of treated water released relative to that consumed and has improved from the year before. The Group has set a 7% improvement target for this ratio year-on-year to increase the volume of water treated by our effluent plants to be recycled and reused within our factory operations and will strive towards this goal for Year 2023 onwards.

| YEAR 2020 mil m³ |

YEAR 2021 mil m³ |

YEAR 2022 mil m³ |

|

| Volume of Water Treated *(Back to local river system) |

1.00 | 1.07 | 0.80 |

| Volume of Water Withdrawn **(Withdrawn from local municipal water source) |

0.29 | 0.84 | 0.62 |

| Ratio (Water Treated : Water Withdrawn) | 3.45 | 1.27 | 1.29 |

| Volume of water withdrawn from a water-stressed region | 0 | 0 | 0 |

*Water treated is equivalent to water discharged

**Water withdrawn is equivalent to water consumed

The Group also primarily operates in Malaysia, within Ipoh, Perak and Subang, Selangor, where, according to the WRI (World Resources Institute), are not considered water stressed areas (https://www.wri.org/applications/aqueduct.water-risk-atlas). The Group targets to maintain these bases and have no immediate plans to relocate to any water-stressed regions in Malaysia or overseas within the next five(5) years. Nevertheless, we acknowledge that floods, droughts and other water related risk issues brought on by unpredictable weather patterns and climate change will likely impact on the way businesses are organized and operated in future.

Solar Panel

Hexcare believes that efficient usage of energy is an important aspect of being a sustainable company and strives to continuously improve in this regard. On a yearly basis, Hexcare is assessed by a qualified registered electrical energy manager appointed by Suruhanjaya Tenaga Malaysia (Energy Commission of Malaysia) on compliance to relevant legislative and regulatory requirements as well as on efficient management of electrical energy. Where practical and economically viable, several cost saving initiatives were also reviewed and implemented throughout the year, such as the adoption and conversion of conventional lightings to LED types at various parts of the plants to improve lighting efficiency and reduce costs.

In the previous year, Hexcare commissioned the installation of a solar photovoltaic power generation system at its plant, at an approximate cost of RM5.0 million, with the intent of harnessing the power of the sun to produce a form of renewable energy that is clean and environmentally friendly. This investment is beneficial to the Group as a hedge against electricity tariff hikes and is a practical viable approach to conserving and managing energy charges. The electricity cost savings predicted from such investment amounts to between RM1.2 million to RM1.5 million per year; this ultimately translates to higher returns to the Group in the long run. As this project was only completed and commissioned in August 2022, the Group had only just begun to gather data on such energy savings for the last five months of FYE2022.

The electricity yield from our solar panels in the previous year was 212,000 kWh, of which 77,000 kWh was utilized at our plants and 135,000 kWh subsequently exported back to Tenaga National Berhad. Based on this preliminary data, the savings generated from solar energy for the first five months of utilization amounted to approximately RM50,000.

3Rs -Recycle, Reduce and Reuse

i) Preservation of Forests and Biodegradability

The 3Rs mantra for the Environment is all the more relevant today as we confront the challenges of climate change, greenhouse gas emissions and depletion of natural resource. Simply put, correct applications of the 3Rs help to reduce the burden on our environment and saves our precious planet.

The world’s forests play a vital role in regulating our climate, absorbing carbon dioxide from the atmosphere and effectively counteract global warming. In our quest to tackle the challenges of climate change and protect the destruction of forests and the precious biodiversity in them, the Group consciously sources its wood and paper products such as packaging materials, wooden pallets and stationeries from Forest Stewardship Council (FSC) certified sources and materials. Products that carry the FSC label are made from 100% recycled materials or are sourced from FSC-certified forests, essentially helping to reverse the effects of deforestation and preserving our environment.

Hexcare’s household and certain industrial gloves produced in Malaysia are largely made from natural rubber – they are recyclable as well as biodegradable in soil where the gloves naturally disintegrate into organic matter over time, causing no harm to the environment or water systems. Where possible, plastic and other synthetic non-biodegradable matters in our shipped goods are also replaced with wood products that are sustainable and renewable.

In another tangible effort to reduce carbon footprint, where possible, the Group also promoted the packaging of gloves in the doubled-up 200 piece-pack or 2,000 pieces per carton style so as to optimize paper and chemicals usage, contributing to less wastes, lower costs and a kinder environment in the long run.

ii) Scheduled Waste

Scheduled waste is any waste that has hazardous characteristics and the potential to impact the environment and/or harm the public if exposed. At Hexcare, responsible waste and pollution management entail the proper and correct disposal of wastes or unwanted by-products in accordance with local environmental laws issued by the Department of Environment (DOE).

The types of scheduled wastes generated by our plants include sludge, clinical waste, waste acetone, contaminated containers and other solid wastes. In FYE2022, latex sludge and compounded latex lumps make up the highest proportion of scheduled waste generated.

| Code | Scheduled Waste Generated | Total Weight (in tonnes) | Disposal Method |

| SW102 | Waste Battery | 0.37 | To reuse, if possible. To dispose to approved disposal facility, if not reusable. |

| SW109 | Fluorescent Bulb | 0.21 | |

| SW305 | Waste Oil | 9.68 | |

| SW321 | Compounded Waste Latex Pump | 293.48 | |

| SW322 | Waste Acetone | 0.13 | |

| SW409 | Contaminated Containers | 61.74 | |

| SW321 | Sludge | 535.71 | Approved disposal facility. Waste management company either landfill or combustion. |

| SW404 | Clinical Waste (RTK) | 0.11 | |

| SW410 | Contaminated Rags | 0.17 |

The disposal and management of such wastes are carried out by competent skilled personnel under the watchful eye of Management to ensure that there is no contamination of ground water, surface water and air quality that could harm the environment or affect human health.

Climate change

The need for climate change risk management is more urgent than ever considering the scale of adverse economic impacts of human activities on the environment today. At Hexcare, we address this risk by computing and monitoring greenhouse gas emissions from the plants' production processes and operations of our offices in Malaysia and Spain.

As a responsible global corporate citizen, we believe that it is important to continuously reduce the impact of GHG emissions from year to year through improving operational efficiencies and applying green technologies where feasible. We established our emissions data table to represent Hexcare’s operational carbon emissions following the guidelines in the Greenhouse Gas (GHG) Protocol, which is a standard governing the accounting and reporting of seven GHG covered by the Kyoto Protocol, and subsequently taken pro-active steps to reduce them. In the process, we have also defined the operational boundaries for the purpose of such calculation, taking into account the scopes of both direct and indirect emissions within the boundaries. The emission factors used were made with reference to recognized sources such as the Malaysian Green Technology Corporation’s website (CDM Electricity Baseline for Malaysia), the Department for Environment (DOE), Food and Rural Affairs (Defra) UK GHG Conversion Factors and the Intergovernmental Panel on Climate Change (IPCC), which are relevant to our operations.

| GHG Emission | CO2e for Year (MT) | |||

| 2020 | 2021 | 2022 | ||

| Scope 1 | Petrol & Diesel | 201 | 201 | 168 |

| Natural Gas | 3,138 | 26,013 | 9,309 | |

| PKS & WC | 29,941 | 27,840 | 17,330 | |

| Sub Total | 33,281 | 54,053 | 26,807 | |

| Scope 2 | Purchase Electricity | 18,382 | 23,495 | 12,200 |

| Sub Total | 18,382 | 23,495 | 12,200 | |

| Total (Scope 1 & 2) | 51,663 | 77,548 | 39,007 | |

| Scope 3 | Purchase goods and services | 55 | 125 | 93 |

| Waste generated in operations | 334 | 641 | 469 | |

| Business Travel | N/A | N/A | 107 | |

| Employee Commuting | N/A | N/A | 278 | |

| Investment | N/A | N/A | 930 | |

| Sub Total | 389 | 766 | 1,877 | |

| Grand Total (Scope 1,2 & 3) | 52,052 | 78,315 | 40,884 | |

Notes:

Scope 1 emissions refer to direct CO2e emitted from sources that are owned by the Group, such as our machineries and company owned vehicles

Scope 2 emissions refer to indirect CO2e emitted from the consumption of purchased electricity

Scope 3 emissions refer to indirect CO2e emitted from the value chain of our company, including both upstream and downstream emissions

In FYE2022, our Scope 1 and Scope 2 emissions saw an approximate 50% reduction in CO2e discharges, from 23,495 metric tons (MT) of CO2e in 2021 to 12,200 MT in FYE2022 due to lower natural gas and purchased electricity consumptions recorded. Further reductions were recorded under Scope 1 itself when we replaced 13 units of diesel-fueled forklifts with 10 units of more environmentally friendly battery-powered ones in the previous year, a decrease of approximately 17%, or 33 MT CO2e saved. Nonetheless, our Scope 3 emission data ballooned in FYE2022 compared to the previous year as we included business travel, employee commuting, as well as investment data in the current year. At the present time, Hexcare will not be disclosing Upstream and Downstream transportation and distribution emissions due to challenges in obtaining data, but will continue our efforts to report this in the future.

Hexcare is committed to decreasing our absolute GHG emissions for Scope 1 and Scope 2 by 35% by 2025, using FY2022 as the baseline, unless otherwise specified. In addition, our Group has set a long-term target to reduce our absolute GHG emissions for Scope 2 by 10% by 2030, using FY2022 as the baseline.

Hexcare is very much conscious of rapidly rising climate change risks, including those that are Physical and Transitional. In response, we proactively identify and manage such risks and opportunities that materially impact our value creation abilities. Driven by our in-house ESG Committee and under the direction of the Board and Management, we acknowledge the following risks and opportunities that are present in our address of climate change issues:

Risks

• Climate change related disclosures and regulations that would impact on our financial and regulatory reporting; and

• Reallocation of financing from financial institutions into other green-intensive investments that would affect our business funding.

Opportunities

• Management of climate change risks and adoption of greener technology could result in less wastages and contribute to overall cost savings for the Group;

• Stakeholders’ trust and perception could be improved through effective emissions management and disclosures; and

• Positive differentiation in the market for long-term value creation that would benefit stakeholders.

Social

Social Sustainability Goals

Achieve 40% female workforce by year 2025

39% workforce are female as at 31 December 2022

| Description / Years | FYE2021 | FYE2022 |

| Female workforce | 37% | 39% |

Achieve 45% female leadership in managerial positions (manager and above) by year 2030

44% leadership in managerial positions are female as at 31 December 2022

Zero tolerance to discrimination, harassment, violence, forced labour and child labour in the workplace

Achieved zero incidence of discrimination or any violence in FYE2022

All manufacturing factories to be ISO 45001 Occupational Health & Safety Management System certified by 2030

We are certified with ISO 45001:2018

Reduce and maintain the work related injuries rate to 0.8 by 2025

Reduced work related injuries rate to 0.93 in FYE2022

Zero incidence of fatalities

Achieved zero incidence of fatalities in FYE2022

| Description / Years | FYE2021 | FYE2022 |

| Work related injuries | 12 | 6 |

| Incident rate | 1.20 | 0.93 |

| Work related fatalities | 0 | 0 |

Some of the Group’s Human Resource Policies that are currently in place include:

Labour Rights Policy

To protect the human rights of employees from the areas of child labour, forced labour, and discrimination with the inclusion of a clear line of responsibilities for the Boards, managers, supervisors, and all the employees.

Workplace Harassment Policy

To prevent unwarranted harrassment of any kind on employees in the workplace. Hexcare has zero tolerance for any form of harrassment.

Workplace Discrimination Policy

To ensure all employees have an environment that is free from discrimination in employment and opportunity due to race, religion, creed, national origin, ancestry, disability, marital status, gender, sexual orientation or age.

Personal Data Protection Policy

To protect the personal data from any loss, misuse, modification, unauthorised or accidental access or disclosure, alteration or destruction.

Zero Recruitment Fee Policy

To ensure that workers especially foreign workers have not been charged recruitment or placement fees during their recruitment process.

These Policies are published on this website, under Investor Relations/Corporate Governance and are available in both English and Malay. There were no incidences of non-compliance to labour laws and regulations that resulted in any fines, reprimands or penalties imposed by any regulatory authorities, both in Malaysia and overseas. At Hexcare, we honour and champion human rights simply because they embody key values in our society such as fairness, equality, dignity and respect.

Communication of our expectations and codes of conduct with regards to these policies are carried out on all new recruits within their first week of employment. We encourage open active communication between employees and Management with regards to these policies.

The people pool at Hexcare has always been culturally diverse with a harmonious blend of nationalities, talents and age groups. As of 31 December 2022, the Group had a total headcount of 814, inclusive of eight local Spanish staff based at our subsidiary company in Spain and human capital of 163 from the merger of Reszon’s workforce. Of this total of 814, 5% or 39 were temporary staff; the rest were full-time permanent staff of the Group. Hexcare also repatriated 205 foreign workers who had completed their employment contract with the Group back to their home countries when international borders and flights resumed in gradual phases during the year. The voluntary turnover rate during the year was approximately 13%. Contractors and/or temporary staff includes those on short-term work agreement contracts with the Group and whose services were terminated upon completion; they accounted for approximately 76% of the total recruited and terminated in FYE2022. Employee movements during the year were as follows:

| FYE2021 | FYE2022 | |

Full-time Workforce Full-time Workforce |

1009 | 814 |

Active Recruitment Rate Active Recruitment Rate |

28.8% | 89.0% |

Voluntary Staff Turnover Rate Voluntary Staff Turnover Rate |

25.5% | 12.7% |

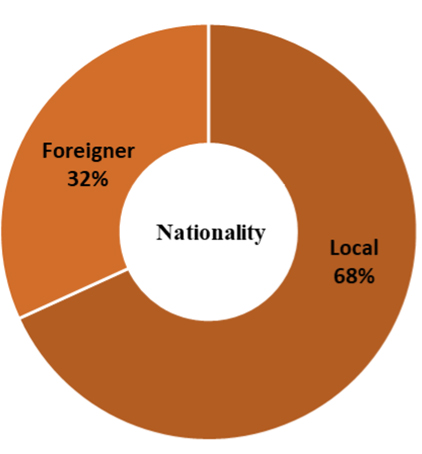

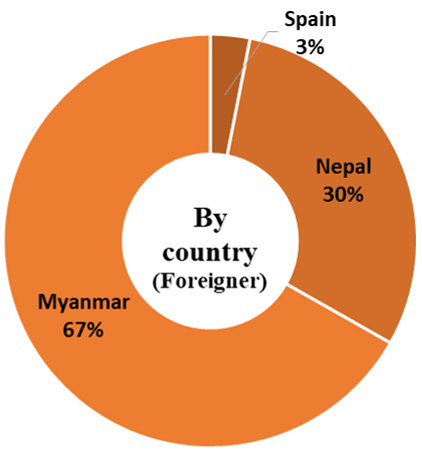

At present, the proportion of local workers to foreigners was higher, at 555 out of total 814 workers or at 68%. The categorization of the Group’s foreign workforce as at the end of FYE2022 consists of workers from Myanmar (67%) and Nepal (30%) brought in to fulfil critical manual tasks at certain sections of the factory floor that require greater continuity and stability in terms of workers’ attendance and turnover. Staff in Spain accounted for 3% of the Group’s workforce. The deliberate decision to employ and retain foreign workers from only a few select countries was so that these foreign workers may foster better support networks, companionship and teamwork among themselves while employed by the Group.

| Number of employees | ||||

| Year/ Nationality |

2022 | 2021 | ||

| Count | % | Count | % | |

| Local | 555 | 68% | 573 | 57% |

| Foreigner | 259 | 32% | 429 | 43% |

| Total | 814 | 100% | 1002 | 100% |

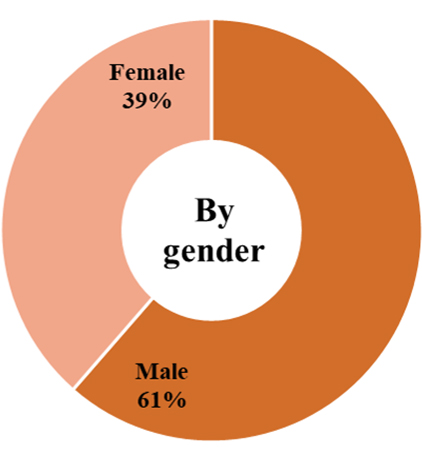

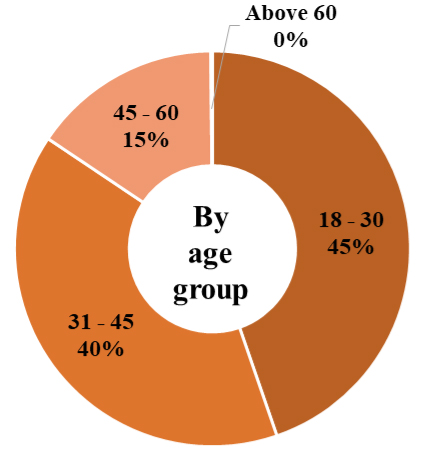

The majority of our Group’s workforce is relatively young and dynamic, with the highest proportion of employees in the 18–30 years age group. Sustainability for the Group is assured from a ready pool of willing, motivated learners, guided by the right balance of qualified experienced mentors. As of the end of FYE22, Hexcare's global workforce comprises 500 males and 314 females, corresponding to 61% and 39%, respectively, as shown in the table below.

| Number of employees | ||||

| Gender/ Age Group |

Male | Female | ||

| Count | % | Count | % | |

| 18-30 years | 237 | 29% | 127 | 16% |

| 31-45 years | 187 | 23% | 136 | 17% |

| 46-60 years | 75 | 9% | 51 | 6% |

| Above 60 years | 1 | 0% | 0 | 0% |

| Total | 500 | 61% | 314 | 39% |

At Hexcare, equal employment opportunities also extend to persons with disabilities. The Persons with Disabilities Act 2008 in Malaysia provides that such persons shall have the right to access employment on an equal basis as persons without disabilities. Opportunities for employment provide persons with disabilities a safe environment to hone their skills, instill confidence and self-independence which would also encourage and inspire others in the community. The Group presently has in its employment two such persons, equivalent to 0.2% of our global staff count, who are attached to our Gloves Operation division. The Group has no qualms in offering more equal employment opportunities to persons with disabilities in the quest to support their livelihood and our local community should and if the need arises

| Description / Years | FYE2021 | FYE2022 | ||

| Count | % | Count | % | |

| Global staff with a disability | 2 | 0.2 | 2 | 0.2 |

Actions Taken to Address Labour Issues

Prevention of child labour

Hexcare does not employ child or under-aged labour, neither does it promote forced labour in its operations. The Group’s Human Resource division takes counter-measures during the hiring process by screening for age using official identification documents such as valid identity cards or passports of workers to verify their ages during the recruitment process. All of our employees meet the current minimum legal recruitable age of 18 years.

Prevention of forced labour

Hexcare does not tolerate any forced labour or labour that involves physical or mental abuse, including actual or threatened physical punishment, verbal or sexual harassment, or domination or restraining of workers by force, authority, or threats. Hexcare shall ensure all work is voluntary and employees shall be free to terminate their employment upon reasonable notice without penalty.

Reduction of excessive working hours

Hexcare is committed to complying with the Employment Act 1955 of Malaysia by upholding decent and ethical working hours for all employees, with a maximum of 104 overtime (OT) hours per month and one rest day per week respectively. Employees are permitted to engage in overtime only if they have not surpassed the daily maximum allowable working hours. To ensure complete compliance with labor laws, we have implemented rigorous monitoring of both rest days and overtime hours through the use of digital tools.

Supporting a living wage

Hexcare is committed to paying at or exceeding the current Minimum Wage Order in order for our workers and their families to be accorded a relatively decent standard of living. Employees are accorded their wages in a fair and orderly manner, which may include approved overtime wages and/or other salary benefits such as fees and allowances.

Mechanisms to allow employee representatives to engage with company management

Hexcare fosters a culture of inclusivity by offering transparent workforce engagement, valuing the input and insights of our employees. Our workforce benefits from a variety of engagement channels, such as:

i. Site visits by our Directors and Management Board members to meet local employees;

ii. Meetings with work councils and trade unions; and

iii. Annual employee surveys

Actions Taken to Improve Workforce Diversity

Hexcare acknowledges that employees are our most valuable asset. We respect and protect human rights, and the Group has taken action to improve workforce diversity, equal opportunities, or reduce discrimination, believing that doing so will motivate our team to foster a healthy working environment conducive to optimal growth.

Race

We are dedicated to promoting racial and ethnic inclusivity. Our efforts involve addressing unconscious bias and selecting local employees who reflect the diversity of the communities we engage with in the countries where we conduct our operations.

Gender

We are committed to enabling the full and meaningful participation of women while ensuring equal leadership opportunities across all levels of decision-making. Hexcare has extended maternity leave to 98 days and paternity leave to 7 days for married male employees.

Religion

We arranged celebratory events to honor the diverse cultures and religions represented by our employees, fostering a sense of unity and connection among our staff.

| Festival Engagement | Details |

| Chinese New Year | gave all employees mandarin oranges received from sustainable suppliers, as well as holding gathering dinners to celebrate the Chinese New Year together. |

| Hari Raya | held celebratory events in several workplace locations, and every Malay colleague brought some food to celebrate Hari Raya with non-Muslim staff together. |

| Deepavali | held celebratory events in several workplace locations, and some of the Indian colleagues brought some homemade Indian cookies to celebrate Deepavali with others. |

Governance

Governance Sustainability Goals

Zero tolerance to bribery or corruption

Achieved zero bribery or corruption cases in FYE2022

Maintain all manufacturing factories certified with ISO 9001 Quality Management System

We are certified with ISO 9001:2015

Maintain all manufacturing factories certified with ISO 13485 Quality Management System (Medical Devices)

We are certified with ISO 13485:2016

In leading corporate governance, the Board of Directors (“Board”) of Hexcare is tasked with this pivotal role of directing the principles of transparency, fairness, ethical behavior and risk management in the Company and within the Group. Where there was no women representative on the Board's Executive Committee in the financial year 2022, the Company had rectified this by appointing two new female members to the Board and Executive Committees on 1st January 2023. Hexcare’s corporate governance practices and applications have been detailed in our Corporate Governance Report uploaded on Bursa Securities and also in our Corporate Governance Overview Statement published in this Annual Report. The Board and Management of Hexcare are likewise guided by the principles and values of the latest Malaysian Code on Corporate Governance (MCCG) 2021 in the conduct of our businesses.

| Description / Years | FYE2022 | FYE2023 | ||

| Count | % | Count | % | |

| Women on the Executive Committee | 0 | 0 | 2 | 29 |

Some of the Group’s Human Resource Policies that are currently in place include:

Whistleblowing Policy

• For every disclosure made in good faith, all concerns or complaints raised will be treated fairly and with confidentially in order to protect the whistleblower.

• Investigation will be conducted in-house or externally by any regulatory agency or authority, and appropriate disciplinary actions will be taken, if applicable. For the year under review, we recorded zero whistleblowing cases.

Code of Conduct & Ethics

• Violating the Code may subject an employee to a poor or unsatisfactory performance review, disciplinary action, including immediate termination, and/or legal actions.

• All applicable laws, rules, and regulations must be adhered to accordingly and always following the higher standard.

Anti Corruption and Bribery Policy

• Hexcare has zero tolerance for any form of corruption or bribery activities and is committed to acting professionally, fairly and with integrity in all business dealings and relationships, whether locally or overseas.

• Giving and/or receiving gifts as well as facilitation payments are prohibited.

These policies are published on this website, under Investor Relations/Corporate Governance and are available in both English and Malay, for the accessibility and convenience of our employees. We are pleased to report that there were no incidences of disciplinary actions or dismissals of employees due to any violations of the above practices in FYE2022.

The table below outlines the attendance of the Directors and Committee members at Company meetings throughout the year 2022:

| Name | Board of Directors | Audit Committee | Nomination Committee | Remuneration Committee | ||||

| Number | Rate | Number | Rate | Number | Rate | Number | Rate | |

| Independent Non-Executive Directors | ||||||||

| Liew Jee Min @ Chong Jee Min | 4 | 4/4 | 5 | 5/5 | 1 | 1/1 | 1 | 1/1 |

| Dato’ Chan Choun Sien | 4 | 4/4 | 5 | 5/5 | 1 | 1/1 | 1 | 1/1 |

| Dato’ Mohamed Bin Hamzah | 4 | 4/4 | 5 | 5/5 | 1 | 1/1 | 1 | 1/1 |

| Non-Independent Non-Executive Directors | ||||||||

| Dato Ong Choo Meng | 4 | 4/4 | ||||||

| Managing Director | ||||||||

| Khoo Chin Leng | 4 | 4/4 | ||||||

| Executive Directors | ||||||||

| Goh Hsu-Ming | 4 | 4/4 | ||||||

| Lim Chee Lip | 4 | 4/4 | ||||||

| Total number of meeting for FY2022 | 4 | 5 | 1 | 1 | ||||

# The Nomination Committee and Remuneration Committees of Hexcare have merged on 1st January 2023, and is now known as the Nomination & Remuneration Committee